The

hammermill you stop thinking about.

Your hammer mill shouldn’t need constant attention. Most do: because they weren’t designed for how material actually behaves in real plants.

.png)

.png)

A different approach to hammer mill design.

We don’t start with a standard mill and modify it.

We start with how material behaves in your operation, and design from there.

1. Material behavior, not just material type

Moisture range, variability, density, and how it actually moves under load.

2. Throughput targets under real

operating conditions

Not nameplate capacity. Sustained, day-to-day reality.

3. Airflow and grinding dynamics as a system

Because consistency and wear are rarely isolated issues.

4. How the mill fits into the existing line

Space, access, maintenance, upstream and downstream constraints.

What this changes in your real operations.

More stable operation across normal variability

Less sensitivity to routine changes in moisture, formulation, and load.

Predictable wear instead of accelerated surprises

Wear patterns that make sense and maintenance that can be planned.

Consistent grind without constant adjustment

Fewer manual tweaks to chase particle size and throughput.

Less operator intervention

The mill supports the process instead of demanding attention.

How this approach is built into the mill.

The outcomes you saw earlier are supported by specific design decisions made before anything is built.

Abrasion-resistant wear surfaces → predictable wear

Airflow control designed as part of grinding → stability

Uniform hammer-to-screen clearance

→ consistent particle size

Serviceability-first design → less downtime

Real execution in the

XM Hammermill Series.

The XM Series takes the design principles outlined above and turns them into physical geometry inside the mill.

Uniform hammer-to-screen clearance

XM mills maintain a reduced, consistent hammer-to-screen clearance around the full grinding chamber. This increases usable screen area, stabilizes airflow, and allows material to exit the grinding zone evenly instead of being forced through by speed or excess horsepower.

Screen utilization designed for real airflow

Rather than relying on higher RPM to overcome restrictions, XM geometry is built to make more of the screen productive. The result is smoother material flow, cleaner particle shape, and stable grinding across coarse and fine screens.

Hammer patterns selected by material behavior

XM hammer configurations are chosen based on how material behaves under load. Inside and outside row patterns are selected to support coarse grinding, fine grinding, or demanding applications like high-fat pet food and high-fiber materials.

Let's build the hammer mill

you stop thinking about.

Built to your specs. Backed by real support. Engineered to keep grinding.

Case Study: Three years.

Zero unplanned shutdowns.

Client: Nemo Feed

Location: Baring, Missouri

Owner: Alvin Burkholder

Application: High-duty feed manufacturing

Equipment: Midwest Custom Engineering XM-Series Hammer Mill

The Challenge

When operating multiple feed formulations with demand surges during key seasons, Nemo Feed could not afford production-stopping failures. Their previous hammer mill suffered from:

• Vibration instability under load

• Frequent bearing and rotor service needs

• Repeat shutdowns at the worst possible times

The maintenance team needed equipment they could trust. No excuses.

The Solution

Midwest Custom Engineering delivered an XM-Series Hammer Mill engineered for continuous uptime through:

• Precision balanced rotor to eliminate vibration faults

• High-hardness wear components to extend service intervals

• Streamlined maintenance access to reduce planned downtime

• Midwest-tough steel construction for nonstop performance

Startup support and maintenance training ensured seamless integration.

“This mill just runs. Reliable, simple, and no drama.”

— Owner, Alvin Burkholder, Nemo Feed (Baring, MO)

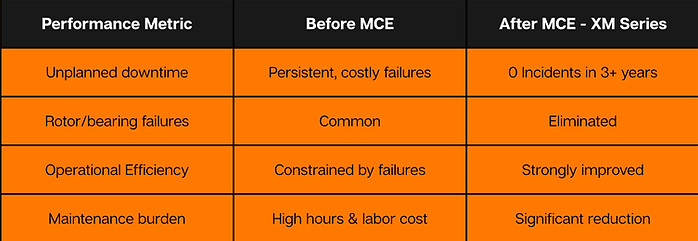

The Results

.png)

.png)