Custom-Engineered Rotary Dryers Built for Your Process

If you want a rotary dryer that actually works for your material, flow, and fuel, you can’t buy it from a catalog. It has to be engineered for your process. That’s what we do.

.png)

.png)

BUILT FOR HARSH CONDITIONS

.png)

LOW MAINTENANCE ACCESS POINTS

.png)

TRUSTED BY BIOMASS & AG PROCESSORS

If your dryer wasn't built for your material... it was never going to work.

Undersized Dryers

Poor retention time, uneven drying, clumped output.

Wrong Burners

Fuel waste, inconsistent heat, and fried product.

Complex Maintenance

Disassembly nightmares, unsafe access, longer downtimes.

Cookie-Cutter Designs

Can’t integrate. Doesn’t scale. Constant headaches.

No Support

Vendor ghosts you? You’re stuck mid-batch.

At MCE, we build it for

your material, your flow rate, your layout.

And we stay around to keep it running.

How we build the right dyrer every time.

Step 1: We Analyze Your Material

You tell us what you’re drying, how much, and your goals. We’ll run moisture tests, flow calculations, and fuel source analysis.

Step 2: We Engineer Your Dryer

From trommel size to flight design to burner match — we spec every detail to your process, not a preset model.

Step 3: We Build It & Stay With You

You get full fabrication, testing, and commissioning. And long-term support from people who answer the phone.

“You don’t need to ‘pick a model.’ You need a dryer that fits your plant, your product, and your priorities. That’s what we build.”

– Jason Shipley, President, MCE

Examples of What We’ve Built. And What We Can Build for You.

Diameters available from 3ft to 13’ - We engineer for your process, not just what we have built in the past.

Proven Across These

Materials & Industries

Biomass & Waste Fuels

Wood chips, sawdust, switchgrass, RDF, ag waste, poultry litter

Built for high-moisture, variable feedstocks with odor- and corrosion-resistant options.

Grain, Feed & Organics

Corn, soybean meal, DDGs, alfalfa, food waste, fertilizer

Precise retention time and burner control for consistent moisture targets.

Recyclables & Chemicals

Plastic, rubber, fiberglass, sludge cake

Dryers designed to handle sticky or sensitive materials, without fouling or bake-on.

Minerals & Aggregates

Gypsum, lime, kaolin, frac sand, lightweight stone

Rugged shells, hard-wearing internals, and consistent high-throughput capacity.

Trusted by Industry Leaders

in Feed, Biomass, Recyclables

Let's Build The Right Dryer for Your Operation

Built to your specs. Backed by real support. Engineered to keep grinding.

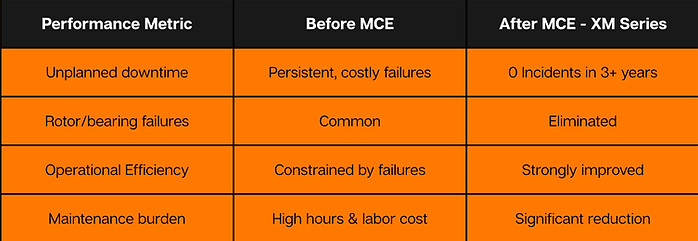

Case Study: Three Years. Zero Unplanned Shutdowns.

Client: Nemo Feed

Location: Baring, Missouri

Owner: Alvin Burkholder

Application: High-duty feed manufacturing

Equipment: Midwest Custom Engineering XM-Series Hammer Mill

The Challenge

When operating multiple feed formulations with demand surges during key seasons, Nemo Feed could not afford production-stopping failures. Their previous hammer mill suffered from:

• Vibration instability under load

• Frequent bearing and rotor service needs

• Repeat shutdowns at the worst possible times

The maintenance team needed equipment they could trust. No excuses.

The Solution

Midwest Custom Engineering delivered an XM-Series Hammer Mill engineered for continuous uptime through:

• Precision balanced rotor to eliminate vibration faults

• High-hardness wear components to extend service intervals

• Streamlined maintenance access to reduce planned downtime

• Midwest-tough steel construction for nonstop performance

Startup support and maintenance training ensured seamless integration.

“This mill just runs. Reliable, simple, and no drama.”

— Owner, Alvin Burkholder, Nemo Feed (Baring, MO)

The Results

.png)