The Ultimate Guide to Hammer Mills for Industrial and Agricultural Grinding

- Jason Shipley

- Aug 5, 2025

- 9 min read

Updated: Aug 6, 2025

Grinding is one of the foundations of production. It doesn't matter if you're feeding livestock, preparing grain for food processing, or moving biomass through a thermal system—if your grinding equipment can't keep up, the whole operation feels it.

Hammer mills have been the go-to choice for industries that need consistent, heavy-duty material reduction. Built to handle high volumes and tough materials, they deliver the kind of uptime and durability that operations rely on day after day.

This guide walks through what hammer mills are, how they work, the industries they serve, and what you should look for when investing in one. Along the way, we’ll link you to detailed resources to help you choose the right model, keep it running strong, and maximize the return on your investment.

Let’s start by breaking down the basics of how hammer mills get the job done.

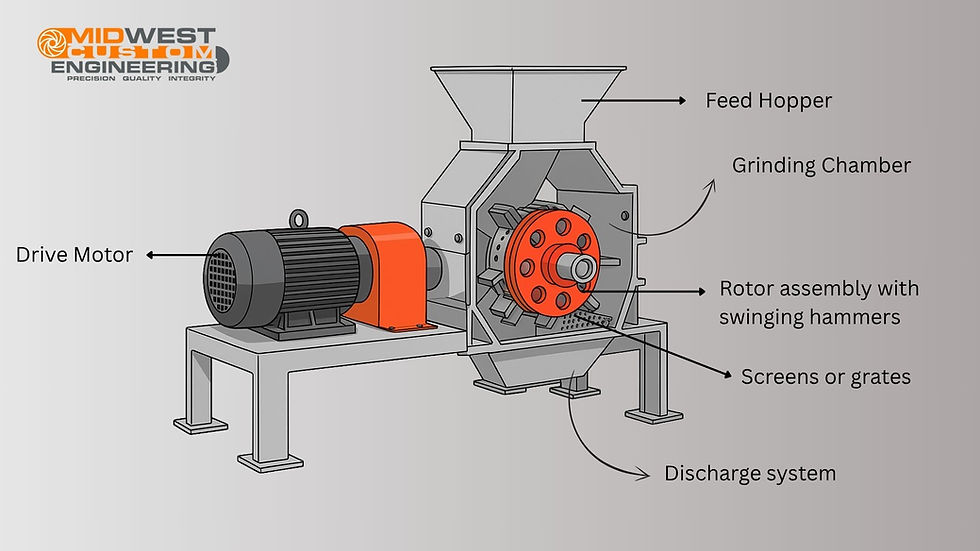

How Hammer Mills Work

At the core, a hammer mill is a simple, brutally effective piece of equipment. Material goes in, impact and force break it down, and the finished product comes out ready for the next step in your operation.

Inside the mill, a rotor spins at high speed. Attached to the rotor are heavy-duty hammers—steel bars or plates—arranged to swing freely. As the rotor turns, the hammers hit the incoming material again and again, breaking it apart by impact.

The material stays in the grinding chamber until it’s small enough to pass through a screen or grate positioned around the rotor. The size of these openings controls the final particle size, giving you flexibility based on what your operation needs.

Key components of a typical hammer mill include:

Feed Hopper – Where material enters the mill.

Grinding Chamber – Where the real work happens: high-speed impact and grinding.

Hammers and Rotor Assembly – The heart of the system, responsible for size reduction.

Screens or Grates – Control the finished particle size.

Discharge System – Moves the finished material out for collection or further processing.

Because of this simple but powerful design, hammer mills can handle a wide variety of materials—from dry grains and corn to fibrous biomass and even some light metal scrap. Adjusting screen sizes, hammer patterns, and rotor speeds allows you to fine-tune the mill for specific applications.

Now that you know how a hammer mill operates, let’s get into how to choose the right one for your process.

Choosing the Right Hammer Mill for Your Operation

A hammer mill needs to do more than just run—it needs to run right for your specific material, your production targets, and your plant conditions. Choosing the wrong setup can lead to frequent maintenance, inconsistent product, and production bottlenecks you simply cannot afford.

Here’s what matters most when selecting the right hammer mill:

1. Know Your Material

The type of material you're processing makes a big difference. Fine, dry grains behave differently inside the mill than fibrous biomass or high-moisture feedstocks.

Soft grains like corn and wheat grind cleanly at moderate speeds.

Fibrous materials like hay or biomass need more space in hammer patterns to allow materials to enter the grinding chamber.

Hard, abrasive materials require heavy-duty rotors and optional wear liners as well as specialized hard facing and sometimes cluster hammer patterns to increase hammer force

2. Match the Particle Size to Your End Product

Hammer mills are built to create controlled particle sizes. Screen size, hammer design, and rotor speed all work together to achieve your target grind.

Smaller screens = finer particle size

Larger screens = coarser grind for less energy use

If particle consistency matters for your next processing step—whether it's pelleting, mixing, or packaging—pay close attention to screen selection.

3. Plan for Throughput and Load Cycles

Daily volume matters just as much as material type. A mill that's too small will clog and overheat. One that's too large will waste energy.

Look at:

Pounds or tons per hour

Duty cycles (continuous vs. batch operation)

Future expansion plans for increased output

4. Think About Maintenance and Access

Easy access to screens, rotors, and hammers matters when downtime costs you money. Look for features like:

Quick-change screens

Bolt-on wear plates

Tool-free access doors

5. Factor in the Environment

Dust control, noise level, and discharge design matter too. If your mill is operating indoors or near sensitive areas, these considerations should be built into the equipment selection.

Want a full checklist to help guide your hammer mill purchase decision?

➤ Read: Choosing the Right Hammer Mill Feed Grinder: What to Know Before You Buy

Hammer Mills for Agricultural Grinding

Grinding is at the heart of agricultural production. Preparing livestock feed, processing grain for food, or producing raw materials for ethanol all depend on consistent, efficient material reduction. The quality of the grind shapes everything from feed conversion rates to processing speeds downstream.

Hammer mills deliver the durability and throughput agricultural operations demand. They are designed to keep production moving even when the material varies in moisture, hardness, or density. Corn, wheat, barley, oats, and soybeans are all processed cleanly with a well-matched hammer mill.

Hammer Mills for Corn Processing

Corn grinding calls for a machine that handles heavy loads without slowing down. Hammer mills set up for corn are built for:

High daily throughput to meet demand

Durable components that resist wear from hard kernels

Flexible screen options to fine-tune particle size, from coarse livestock feed to finer meal

Get deeper insights into corn-specific grinding systems here: ➤ Read: Hammer Mills for Corn: Grinding Power That Keeps Up with High-Volume Demand

Hammer Mills for Grain Processing

When handling multiple grains in one operation, reliability matters even more. A well-designed grain hammer mill ensures:

Consistent grind quality for better mixing and processing

Clean material discharge with minimal dust carryover

Steady performance during long, continuous production runs

Learn more about choosing the right hammer mill for mixed grain grinding: ➤ Read: Hammer Mills for Grain: A Durable Choice for Continuous, Clean Grinding

Industrial Applications of Hammer Mills

Grinding needs aren't limited to agriculture. Across a wide range of industries, hammer mills are relied on to reduce materials efficiently, consistently, and with minimal maintenance demands. Their design makes them adaptable to many types of production environments.

Here are some of the industries where hammer mills play a critical role:

Food Processing

Grinding spices, grains, and other food products requires consistent particle size and cleanliness. Hammer mills are widely used in food production for:

Grinding grains for cereal and baking mixes

Size reduction of spices and flavorings

Pre-processing food waste for composting or recycling

Biomass and Renewable Energy

In biomass production, material consistency affects drying, combustion, and pelletizing. Hammer mills process:

Wood chips and sawdust

Agricultural residues like corn stover

Biochar fines for energy systems

Pharmaceuticals and Chemicals

When handling bulk powders or preparing materials for blending, hammer mills are valued for:

Producing uniform particle sizes for tablets and capsules

Grinding chemicals for blending or reaction processes

Sizing materials to meet specific formulation requirements

Recycling and Waste Management

Recycling operations need grinding systems that can handle tough, unpredictable materials. Hammer mills support:

Shredding plastics before reprocessing

Crushing light metals

Size-reducing paper, textiles, and other post-consumer waste

Mining and Aggregate

Material toughness and high throughput are critical in mining and minerals. Hammer mills are used for:

Crushing limestone, gypsum, and other minerals

Preparing aggregates for mixing or processing

Grinding ores for easier handling or chemical treatment

Explore more examples of how hammer mills support major industries:

➤ Read: Top 5 Industrial Applications of Hammer Mills

What to Look for When Buying an Industrial Hammer Mill

Choosing an industrial hammer mill isn’t about picking a machine off the shelf. It's about matching the equipment to the specific demands of your operation — the material, the volume, the environment, and the long-term goals.

Here’s what needs careful attention when you're evaluating hammer mills:

Rotor Design and Speed

The rotor is the driving force inside the mill. A well-balanced, high-quality rotor ensures consistent grinding and minimizes vibration. Rotor speed directly impacts particle size and production rates. Faster speeds create finer grinds, while slower speeds can be more energy-efficient for coarser material.

Hammer Configuration

Hammer thickness, number, and pattern affect how material is broken down. Reversible hammers can double wear life. Adjustable configurations allow the mill to adapt to different materials without needing a completely different setup.

Screen Selection

Screens control the final particle size and the flow rate through the mill. Quick-change screen assemblies reduce downtime and make it easier to fine-tune your end product.

Build Materials

For abrasive or corrosive environments, standard carbon steel won't last. Look for mills built from stainless steel or abrasion-resistant (AR) steel if you're working with harsh materials like minerals, biochar, or industrial waste.

Access and Maintenance

Downtime costs money. Easy access to key wear parts — like screens, hammers, and liners — makes routine maintenance faster and less disruptive. Tool-free access doors, bolt-on wear plates, and modular assemblies are all worth considering.

System Integration

Think about how the hammer mill will fit into your overall process flow. Discharge configurations, dust collection compatibility, and material handling systems need to connect cleanly and efficiently.

For a deeper guide to evaluating your next hammer mill investment: ➤ Read: What to Look for When Buying Industrial Hammer Mills

Hammer Mills vs. Other Grinding Solutions

Grinding systems come in a lot of shapes and sizes. Hammer mills are a proven option, but understanding how they differ from other types of grinding equipment helps you make a smarter decision for your operation.

Hammer Mills

Strengths: Simple design, high durability, flexible particle sizing, and the ability to handle a wide variety of materials without extensive adjustments.

Best For: Agricultural feed grinding, biomass preparation, food production, recycling, and material prep in mining operations.

Roller Mills

Strengths: Fine control over particle size with less dust generation in specific applications.

Best For: Uniform particle sizing in flour production or specialized food processing where very fine control is needed.

Impact Pulverizers

Strengths: Extremely fine particle production for chemical or pharmaceutical applications.

Best For: Ultra-fine grinding of powders when standard particle size reduction isn't enough.

When Hammer Mills Stand Out

Hammer mills hit the sweet spot for operations that need rugged reliability, simple maintenance, and flexibility across different material types. In heavy-duty environments—where uptime matters more than lab-grade precision—hammer mills consistently deliver better value over time.

When your production floor needs a grinding solution that keeps moving no matter what’s thrown at it, hammer mills remain one of the most dependable options available.

Maintenance Tips for Long-Term Hammer Mill Performance

A properly built hammer mill is designed for heavy use, but even the toughest machines need regular care to stay efficient and avoid unexpected downtime. A solid maintenance plan doesn't just protect your investment—it keeps production moving without surprises.

Here’s how to keep your hammer mill running strong year after year:

1. Inspect Hammers and Screens Regularly

Hammers, pins, spacers, and screens are all wear parts. Check them weekly, or more often if you're running abrasive materials. Replace worn or broken hammers immediately to maintain consistent grinding and protect the rotor.

Look for hammer rounding or edge wear.

Inspect pins for wear from hammers

It is best practice to replace the pins and spacers at the same time as hammers, but some operations choose to replace this periodically as needed.Inspect screens for cracks, holes, or clogged openings.

2. Monitor Rotor Balance

Even slight imbalances in the rotor can cause vibration, reduce grinding efficiency, and stress other components. If you notice increased vibration or noise, stop and check hammer wear and rotor alignment.

3. Keep Bearings Lubricated

Bearing failure is one of the leading causes of unplanned downtime. Follow manufacturer lubrication schedules closely and use the right grade of grease or oil recommended for your mill’s operating conditions.

4. Clean the Grinding Chamber

Build-up inside the chamber reduces grinding efficiency and can cause overheating. A quick visual inspection after every shift and a thorough cleanout at scheduled intervals keeps material flow smooth.

5. Set a Preventative Maintenance Calendar

Waiting for a breakdown before doing maintenance costs more every time. Create a basic schedule for:

Daily visual checks

Weekly inspections

Monthly deep maintenance

Annual rebuilds or component replacements if needed

A few minutes spent checking wear parts and bearings saves hours—or even days—of downtime later.

Hammer Mill FAQs

Still working out the final details of your hammer mill project? Here are answers to some of the most common questions.

How do I size a hammer mill for my operation?

Start with your material type, the desired finished particle size, and your target throughput (in pounds or tons per hour). Rotor speed, hammer configuration, and screen size will all be selected based on these factors. Working with an experienced supplier ensures the system is properly matched from the beginning.

How often should I replace hammers and screens?

It depends on the material you're processing and your run times. In high-abrasion applications like grinding minerals or biochar, inspections might be needed weekly. For lighter materials like corn or feed grains, wear checks every few weeks may be enough. Always replace parts before excessive wear leads to rotor imbalance or inefficient grinding.

Can a hammer mill handle wet materials?

Hammer mills can process materials with some moisture, but high-moisture content can cause buildup, clogging, and inconsistent particle size. For materials over about 15% moisture, drying before grinding—or choosing a specially designed mill—is usually recommended.

How much maintenance does a hammer mill really require?

Routine inspections, lubrication, and occasional replacement of wear parts are the main needs. A properly maintained hammer mill can operate reliably for years without major rebuilds.

Final Thoughts: Why Hammer Mills Still Lead the Way

In industries where material processing drives production, equipment reliability isn’t negotiable. A well-designed hammer mill brings a simple promise: it keeps working when you need it most.

Built for durability, adaptable across materials, and easy to maintain, hammer mills remain a trusted solution for agricultural, industrial, and manufacturing operations alike. They deliver consistent results, handle tough jobs without complaint, and scale with your needs over time.

Choosing the right hammer mill—and maintaining it with care—gives your operation an edge: fewer breakdowns, better product consistency, and a grinding system you don’t have to second-guess.

If you’re planning a new project or upgrading existing equipment, Midwest Custom Engineering can help you match the right hammer mill to your operation’s demands. Let's build a solution that keeps your production moving day after day.

.png)

The timeless appeal of the 8 Ball Jacket continues to dominate streetwear fashion, blending vintage vibes with a bold statement look. Known for its cultural impact since the late ‘80s and early ‘90s, this jacket remains a symbol of individuality and confidence. If you’re looking for authentic designs that stand out, explore the full collection at Stussy Jacket.